Cason | Stainless Steel Sow Pig Feed trough for pig farm - feeder | Feeding Equipment Wholesale

- group name

- Feeding system

- Min Order

- 1 piece

- brand name

- Cason Breeding equipment Manufacturer

- model

- Sow Feeder

- Nearest port for product export

- Qingdao Port

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, MoneyGram, Credit Card, Westem Union, Cash

- update time

- Sat, 04 Feb 2023 16:33:40 GMT

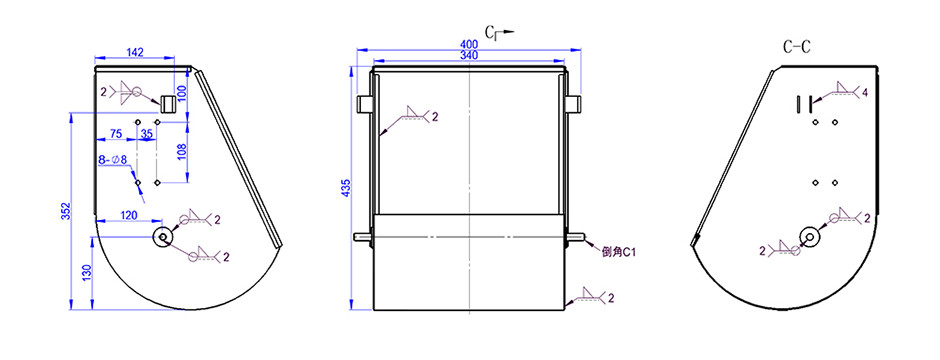

Paramtents

Material 304 stainless steel

Thickness 1.2 or 1.3 mm

weight 5-6.5 kg

Packge wood pallet

Packging & Delivery

- 45cm x35cm x50cm

-

Min Order1 piece

Briefing

Detailed

Feed troughs have a

significant impact on the amount of feed wasted. According to researchers'

estimates, at least 10% to 15% of the feed provided by large-scale pig farms to

growing and finishing pigs is not eaten by the pigs, but during the feeding process.

It is wasted and eventually discharged with sewage.

Choosing a suitable

hog feed trough will obviously reduce feed waste and fecal contamination,

improve pig production performance, and thus increase the economic benefits of

farming hogs .Therefore Cason feed trough has a baffle to prevent feed waste

caused by sows during feeding .

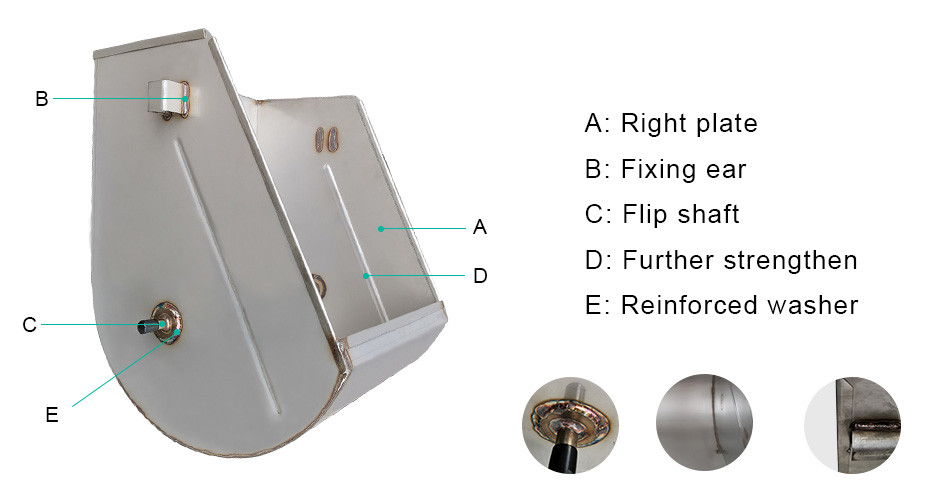

Advantages of Cason Pig Feed Trough

A reinforcing rib is punched on the side plate to further

strengthen the shape to prevent the trough from deforming when the sow eats.

All

welding points are fully welded, and there is no leakage or virtual welding.

The flipping shaft is welded to the side plate through a washer to avoid damage

and shedding during long-term use. And at the same time, it guarantees the

tightness of hog feeder trough and prevents leakage.

A

plastic holster is sleeved on the shaft to avoid scratches caused by collision

and friction during transportation, which affects the appearance.

The

side-curved of Cason Feeder design has no dead spot on corners . so there is no

pile up of hog feed .

Cason

sow feed trough can be flipped freely for easy cleaning. While cleaning, you

can use a high-pressure water gun.

Cason

Sow trough Production process

Precautions

If no waste of feed, the consumption of

feed is equal to the feed intake of pigs, which requires us to pay attention to

the daily management of the trough, timely repair and replace the long-used and

damaged trough, according to the different pigs. Select the appropriate feed

trough at the different growth stage, and the feeding space of the

trough should meet the requirements of different weight pigs under different

feeding modes to reduce the loss caused by feed waste.